Tel

0577-62795555

Tel

0577-62795555

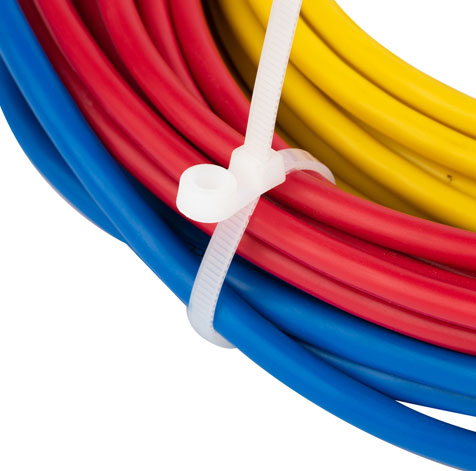

When it comes to organizing and securing items, cable ties play an indispensable role. Commonly made from durable materials such as PA66 nylon, cable ties, also known as zip ties, are versatile tools that can handle a wide range of bundling tasks. However, selecting the right nylon cable tie requires consideration of several factors including length, width, and tensile strength.

The first aspect to consider is the length of the cable tie. If you’re working with a larger bundling diameter, you'll need longer nylon cable ties. For instance, if the diameter of the items you’re bundling is 22mm, a 100mm long cable tie would be appropriate. Ensuring the right length not only helps in securing the items properly but also provides a neat and tidy appearance.

The width of a cable tie is essential in determining the amount of force it can withstand. For example, if your application requires the bundle to endure a force of 8 kilograms, a cable tie with a width of 2.5mm will suffice. However, if you anticipate needing to support a force of 10 kilograms, you might consider using a reinforced cable tie. These reinforced zip ties are designed to handle greater stresses without incurring significantly higher costs.

One of the advantages of using PA66 cable ties is their cost-effectiveness. Reinforced cable ties, which offer higher tensile strength, allow you to meet your specific requirements without overspending. This ensures that you can achieve the desired level of security and reliability without compromising your budget.

In summary, selecting the right cable tie involves more than just picking the first pack off the shelf. By considering the dimensions and the required tensile strength, you can ensure that your nylon cable ties or custom zip ties perform optimally for your specific needs. Whether you are organizing cables in a data center or securing items for transport, choosing the right PA66 cable tie can make all the difference in achieving a secure and reliable bundle.